Product Description

Ultra high strength epoxy paving grout – suitable for vehicular areas up to 10 tonnes

Similar to ProJoint™ Fusion™, ProJoint™ TITAN™ offers a quick and easy solution to filling joints between paving slabs and setts but in areas of both vehicular access and general foot traffic.

Replacing the 3.5 t Max product but with superior performance .

Suitable for natural stone and concrete paving, ProJoint™ TITAN™ is a high strength two-part epoxy paving grout and is very simple to use. Resin and sand are supplied ready-mixed within the tub, and only requires the addition of the enclosed hardener to activate the chemical cure. Once cured, ProJoint™ TITAN™ delivers a weed-free, frost resistant joint which resists pressure washing.

KEY FACTS:

- Permeable bedding mix not required

- Part mixed components for fast application, all supplied within the mixing tub

- Professional strength, self-compacting and suitable for joint widths of 5mm upwards

- Weed, pressure washer and frost resistant

- Ideal for paths and patios as well as driveways or other vehicular areas (up to 10 tonnes)

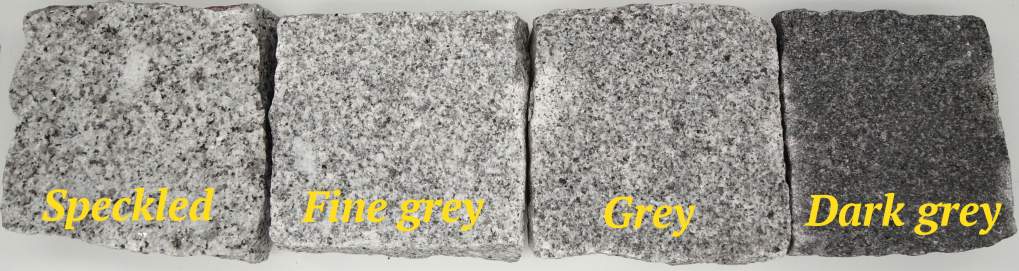

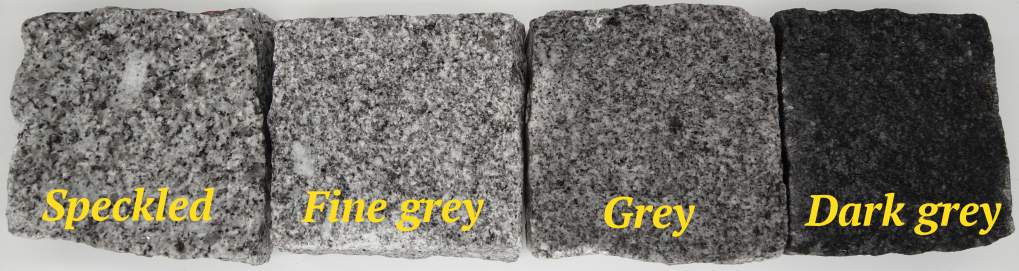

- Suitable for natural stone and concrete paving, setts and slabs